Vertical roller mill: good performance and popular

Time:2015-04-21

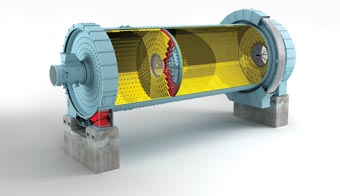

Vertical roller mill is based on general mill, a new type of milling machine design, its advantage makes the production cost greatly reduced its simple system, high production efficiency, compact layout, and can open layout, energy saving and environmental protection. Especially the advantages of low energy consumption of vertical mill system, so that it gradually for the domestic cement, electric power, chemical industry, and warmly welcomed by the industry, has become the preferred equipment for grinding.

The advantage of a lot of people on it is still not very clear, in the end what it has specific advantages?

First, from the economy, its configuration and low cost, for customers to save a lot of money. Vertical mill and ball mill system has the advantages of simple process flow, compared to cover an area of an area can be reduced by about 50%, the configuration cost is reduced by about 70%, compared to the general grinding machine, its construction area of small, less occupied space; it is the set of crushing, drying, grinding, grading conveying in one, the system is simple, compact layout. Can open layout, reduce distribution costs.

Second, in actual operation, the operation cost is low, the process is simple, easy to operate. It's a small loss, with special material, liner and grinding roller and long service life, reduce operating costs, utilization rate is high; its grinding efficiency is high, the vertical roller mill grinding roller and grinding the material bed grinding material, so the energy consumption is low, the power consumption of the milling system 40-50% lower than the milling system is equipped with internal circulation device,; to further reduce power consumption; large feeding size, up to about 5% of the diameter of roller.

Third, the drying capacity of the mill, vertical mill by gas conveying material in grinding the material moisture content, large, can control the inlet air temperature, so that products meet the requirements in the final moisture, drying and grinding the materials in the 12~15%; it's product quality is stable, the average particle size, residence time of material in the mill in short, the product quality is stable.

Fourth, its operation easy to implement. Because it is equipped with automatic control device, can realize remote control, simple and easy operation; in addition, to prevent the roller and disc lining device in direct contact, avoid the breakage of the violent vibration, makes it run more smoothly.

Environmental protection, energy saving is the main performance characteristics of it, in the work, the small vibration, low noise, little dust, clean operation environment, consistent with the requirements of environmental protection, to make it more color.