Raymond mill elastic shock absorbing mechanism

Time:2019-03-27

Raymond mill elastic shock absorbing mechanism

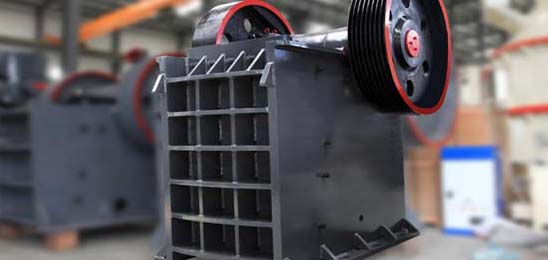

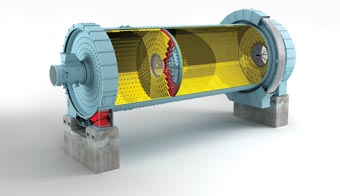

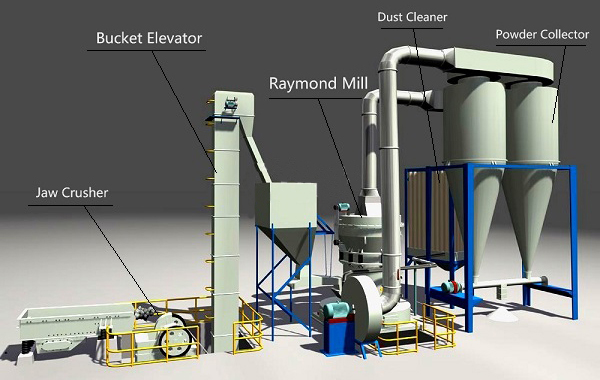

When the Raymond machine is working, the material to be pulverized is fed into the machine from the feeding hopper on the side of the hood, and the grinding roller device suspended on the main stand of the main machine is revolved around the vertical axis, while rotating itself, due to the centrifugal force during rotation. The role of the grinding roller swings outward, pressing against the grinding ring, so that the blade shovel the material between the grinding roller and the grinding ring, and the purpose of pulverizing the material is achieved by rolling rolling of the grinding roller. After the material is ground, the fan blows the wind into the main casing, blows up the powder, and sorts it through the analyzer placed above the grinding chamber. The material with too fineness falls into the grinding chamber and re-grinds, and the fineness meets the specifications. Enter the cyclone collector with the wind flow, collect it and discharge it through the powder outlet, which is the finished product. The wind flow is returned to the fan by the return air pipe at the upper end of the large cyclone collector. The air path is circulated and flows under the negative pressure state. The increased air volume of the circulating air path is partially discharged through the exhaust pipe between the fan and the main engine, and enters the small cyclone collection. The device is cleaned.

In the operation of Raymond machine, the vibration of the grinding roller produces great vibration, which causes great noise in the workshop and affects the environment around the factory. The elastic damping mechanism of Raymond mill solves the existing problems.

The elastic damping mechanism of the Raymond mill includes a main body composed of an analysis chamber 1, a grinding chamber 2, and an inlet volute 3. A frame 5 is disposed under the main body, and a cushion 7 is disposed on the frame 5 The main body is mounted on the cushion 7 .

The elastic damping mechanism of the Raymond mill has the following features: the cushion 7 has a thickness of 10-100 mm. Preferably, the cushion 7 has a thickness of 30-60 mm.

The elastic damping mechanism of Raymond Mill has a cushion on the top of the frame, which can reduce the vibration generated by the operation of the equipment and reduce the noise in the workshop.