What are the vertical mill cement finish grinding

Time:2015-04-22

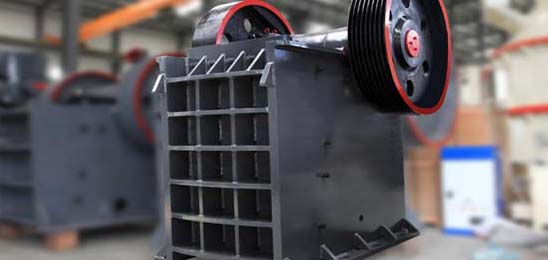

Base on the plentiful experience of producing and marketing of impact crusher, MCC R&D institution designed the PFW series impact crusher. It is the newest style impact crusher and has been widely used in many industries, like chemical, metallurgy, road and bridge construction and sand making and so on.

OK grinding is the meaning of Onoda and Kobe (Onoda cement company) steel (Kobe Steel Mill) to cooperate in the development, currently used for cement and blast furnace slag OK mill has more than 20 units, such as Japan, South Korea, India, Greece, Japan is used, a cement company will also use clinker grinding cement this in 2000..

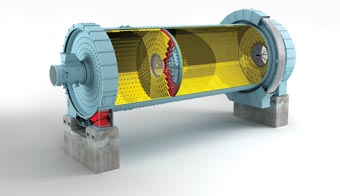

OK grinding and milling the table shown in Figure 3, the process of OK mill. OK mill, 27-4, 30-4 models are 25-3, 33-4, 36-4 5, 25-3 3 roller mill, the remainder is 4 and. OK vertical mill grinding clinker production was 55 ~ 165t/h, the slag yield is 35 ~ 100 t/h, grinding with OKS high efficiency separator, a grinding roller turning device.

The vertical mill cement grinding power consumption is low, grinding cement does not need auxiliary cooling, and the residence time of the material in the mill is very short, can quickly convert from one species to another species, does not need to be a lot of grinding material out, but also in the production process of rapidly changing product particles. Vertical grinding pressure is small, generally less than 10 dB, so from the above situation, the use of cement vertical mill as the final grinding equipment is advantageous. But when the vertical mill grinding cement, may have the problem of low grinding temperature. If the grinding temperature is lower than 80 DEG C, two water gypsum can be transformed to semi hydrated gypsum, cement retarder phenomenon will happen, at this time should be to the mill of hot air. In addition, when the grinding roller mesh is bad, can be resolved through to the mill spray.

Modern roller roller diameter up to 2 m, and up to 1.4 m, the extrusion pressure of about 50 ~ 350 MPa, grinding roll around the line speed of about 1 ~ 2.0m/s, the high level of energy utilization, has now reached 600m2/kJ (vertical mill is 450 m2/kJ, the level of 500m2/kJ roller mill, ball mill is 240 ~ 320 m2/kJ).

In the early days, the roller working reliability is not satisfactory, mainly gear transmission device and the grinding roller surface wear. With the advent of wear resistant materials and the accumulation of operating experience, the roller service life is increased greatly. In the length direction of the grinding roll gap between uniform distribution and control the pressure at 6 MPa (6000 kN/m2) the following, is good for the long-term stability of the roller, the best feeding size of not more than 1.5 ~ 2 times of the width of the gap. Compared with a ball mill, composed of roller press, mill and separator cement finish grinding cycle system, in the same grinding material, the maximum energy saving more than 50%.

But the roller press grinding cement, average particle size distribution is narrow, and easy bad, cement normal consistency water demand is big, but it can be adjusted by the powder selecting machine, broaden the cement particle size distribution to solve. With roller press grinding cement grinding mill, also has the problem of low temperature ratio. So, with roller press for cement finish grinding, is more suitable for the grinding of cement clinker is inert, without too much of the plaster of Portland cement, lest produce cement retarder. In the cement pre grinding system, the general trend in the use of roller press or specially used for grinding mill stand as a pre pre grinding, then the composition of grinding system with ball mill, this combination of high grinding efficiency, energy saving and had no effect on the quality of cement.

In several pre grinding process, if we can increase the load cycle pre grinding part, namely the use of coarse powder separator to increase the circulation of coarse powder, then the system can improve the efficiency of grinding. Due to mechanical problems of vertical mill is relatively small, so the special equipment for cement pre grinding process has recently been extended. In recent years, the development of roller press manufacturers and users to continue to roll press operation experience increases, the reliability of roller press has been greatly improved. In the cement finish grinding system, ensure the quality of cement from the point of view, the special vertical mill is better.