Verical Roller Mill

Vertical roller mill is MCC company to solve the industrial mill production is low, high energy consumption, technical difficulties, the European advanced technology absorption and mill design combined with the company for many years the concept of advanced manufacturing and market demand, after a hard grinding at large improvements in equipment design. Structural design of vertical roller mill is used reasonable and reliable, with advanced technology, drying, crushing, separator, promote the integration, especially in the large grinding process, and fully meet customer demand, the main technical and economic indicators have reached the international advanced level.

Vertical roller mill has become the first choice for the cement industry, raw material grinding, it is estimated there are more than 600 sets of production. Large vertical mill capacity has reached 600t / h, the transmission power of 5000KW. In the early 1990s, cement grinding mill stand areas has progressed, there are many large mill production. The basic process is the vertical mill finish grinding, but in order to pre-grinding and roller presses to compete, adapt to the pipe milling system transformation, and Japan since 1987, has developed a vertical mill pre-grinding system, and gradually be developed.

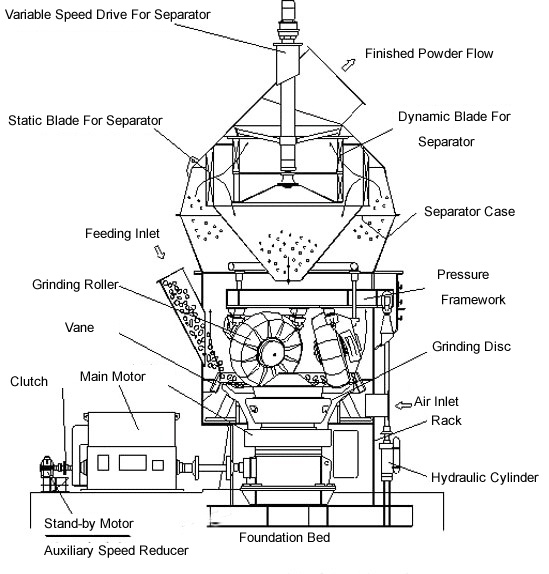

The design idea of vertical roller mill

Grinding principle of vertical roller mill is the use of 2 ~ 4 rollers to the disc, as the speed of rotation the ground material, basically belongs to the material layer grinding. The material is mainly due to the rolling action of grinding roller and grinding in the mill, the grinding roller and disc rotation speed difference between, so has the shear milling. Effect of feeding disc center materials due to the centrifugal force of the rotating disc, disc mill roller to move into the surrounding between roller and disc. Effect of roller grinding in the hydraulic device and a pressurization mechanism, applied to the grinding pressure of roller material in.

The material is compacted crushed after to continue to move from the edge of the grinding disc, the disc edge overflow dam. At the same time, the hot air from the annular nozzle millstone around high speed up to, the coarse particles blow back disc re grinding, drying and suspended material. The fine powder into the upper part of the air separator for separation, reached a certain particle diameter of qualified fine powder with air from the upper overflow mill and collected, coarse grinding disc and the material feeding back again with grinding.

Verical Roller Mill Types

According to the current development trend of powder industry in our country, the performance advantage of vertical roller mill is extremely powerful in all kinds of grinding equipment, according to the need of production, I plant design and production of two major categories of mill type, respectively is LM series of vertical roller mill and LUM vertical roller mill. I plant design and production of the mill has played an important role in the fly ash, slag, calcium carbonate powder and the production process of pulverized coal, become the first choice for superfine grinding process, get customers alike. The mill is taking a double harvest of economic benefits and environmental benefits of the road, on behalf of the development direction of the mine grinding equipment in China in the next few years.

Working Process of Vertical Roller Mill

Grinding process materials are: motor through reducer drive disc rotates, the material falls under the spout from the central disc, mobile and by rolling the roller to the edge of the disc under the effect of centrifugal force, leaving the material crushed disc, is to speed up the flow and vertical mill with integrated splitter, splitter after meal after returning to the disc, re-grinding

Powder into the air out of grinding down the dust collection system to collect system, is the product. In the vertical mill by pneumatic conveying materials, a larger air flow, which can use the waste heat from the gas, while drying the grinding operation.

Application of Vertical Roller Mill

(1) the mass production of special steel, thermal power plant, cement plant, coal preparation, coal gangue powder

(2) the power plant desulfurization limestone grinding equipment and large-scale ore milling of non metallic minerals industry

(3) ultrafine grinding glass processing industry, pyrophyllite powder quartz

(4) special steel slag and blast furnace slag, slag and fly ash grinding plant

(5) a large number of chemical industry production of flour additives

(6) the construction industry a variety of grinding slag powder and cement clinker

Features

- 1. The grinding roller for tyre shape, so that the sliding wear is reduced greatly, prolong the service life. The high chromium alloy steel lining plate roll grinding and abrasion, the crystalline phase microstructure is martensite wear-resistant carbide on the body height (WC, TiC) of hard phase, in addition to containing Cr20% or more, and expensive, V, Ti, W, Mo, Mn, Cu and other alloy elements, so that the life of wear-resistant parts extension.

- 2. The special roller pressure, pressure adjustable, to alleviate the impact force, a limiting device, which can effectively prevent the direct contact between the rollers and millstones, can avoid the strong vibration mill in cutting, does not normally occur, reduce the abrasive wear.

- 3. The thin oil circulation lubrication, greatly improve the life cycle and the operation rate of the machine bearing.

- 4. The two roller structure. Grinding in a large space, the grinding roller hydraulic device out of machine body can be used to replace or repair, maintenance is convenient.

- 5. According to the special needs of customers, to cancel the slag scraper, increase reliability, energy saving. The grinding roller and grinding of bearing seal is communicated with the atmosphere, is not affected by the grinding dust, so do not need to configure a seal fan, can reduce the oxygen content of the seal wear and energy consumption of the fan.

Request for Quotation

You can get the price list and a MCC representative will contact you within one business day.