Why SBM Heavy Industry ZS Efficient Sand Maker Hammer is More Worn

Time:2018-05-24

Why SBM Heavy Industry ZS Efficient Sand Maker Hammer is More Worn

As the core component of the sand making machine (sand making machine), the hammer of the sand making machine, after a long period of production and operation, is the most easily worn component of the sand making machine. And why the SZ heavy-duty ZS series of high-impact sand making machine hammer is more wear-resistant, longer life, the following Xiaobian bring you to find out.

It is believed that the users who are familiar with the mechanical industry or use high-manganese steel hammers have such an experience. With a certain period of time, the hammerhead wears very seriously, and even the phenomenon of fracture may seriously affect the working efficiency of the entire sand making machine. Virtually increase the user's operating costs. After careful research and discussion, SBM has turned its sights to a more wear-resistant alloy material, a high-chromium alloy. High chromium alloy hammers have higher wear resistance and toughness than high manganese steel hammers, depending on the superior properties of high chromium alloys.

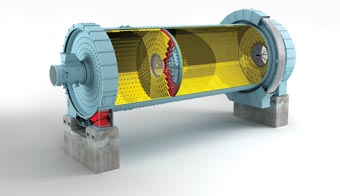

- 1. High-chromium alloy products are treated with advanced technology. It has features such as high quenching hardness, high toughness value, and strong stability, so that it has good wear resistance and shows excellent cost performance. Can adapt to the mining industry wet grinding, dry grinding, mixed grinding and so on.

- 2. The high-chromium alloy substrate is densely packed and densely strengthened. It can resist harsh abrasive wear, optimize the heat treatment process, and perform water toughness treatment.

- 3. The high-chromium alloy products use a special dual medium quenching agent with good thermal stability as the medium, so that the products can achieve high strength, high hardness and high toughness to meet the wear-resistant process requirements.

SBM Heavy Industries has always been striving for excellence. It has strict requirements on product quality and strictly controls all parts of the sand making machine. The hammer of the sand making machine is made of high-chromium alloy material, allowing its service life to be more than double the service life of conventional hammers. The frequency of hammer replacement is greatly reduced, and the overall production efficiency of the sand making machine is also improved.