How to effectively solve the problem of Raymond mill in the process of production and processing?

Time:2019-03-27

How to effectively solve the problem of Raymond mill in the process of production and processing?

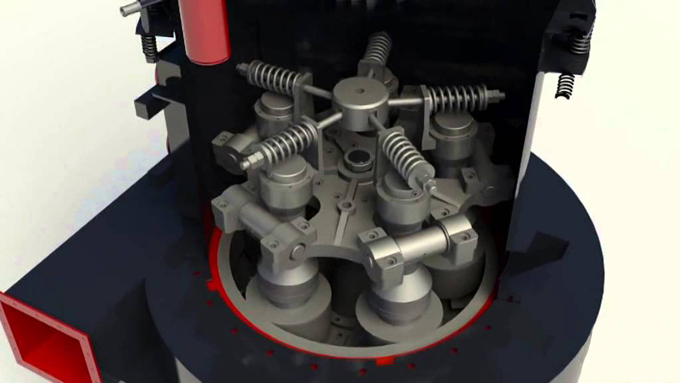

Raymond mill is an indispensable part of the milling industry. However, as a mechanical device, it is inevitable that failure will occur in production and processing. Failures are not terrible. As long as the solution and repair can be completed in time, the enterprise can develop rapidly and long. How to effectively solve the problem of the froster in the production and processing?

As a more common equipment in the milling industry, the Raymond mill plays an important role in the milling production line, and it also has a large loss during work, so you need effective maintenance and maintenance. In order to guarantee the life of the equipment. If the Raymond mill malfunctions while working, the first thing to do is to know where the fault is.

1. For example, if the Raymond mill has abnormal sound during the grinding process, the first thing to do is to stop the material to be fed, and then check the material inside the Raymond mill after it is removed.

2. There is also a reasonable position to ensure that the Raymond mill airway inspection hole is reasonable, so that it can facilitate the later cleaning work. The thickness of the air duct steel plate should be qualified, and it is not easy to rust, the welding should be strict, and the air should not be leaked.

After we have processed and produced, we must carefully and thoroughly check the various components of the Raymond machine. For example, check the fastening of the bolts, how the lubricating oil is used, whether the connection parts of the parts are firm, whether the motor voltage is normal, etc., and also check the lightning before the machine is turned on, and find out in time. The potential problem exists, which is an important step to reduce the failure of the Raymond mill.