Sand Production Line Introduction

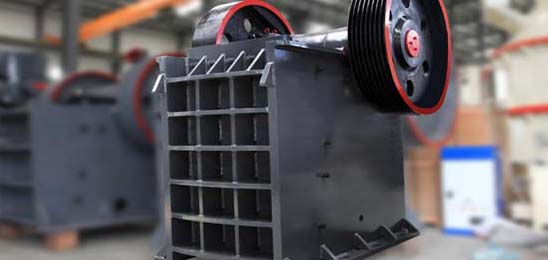

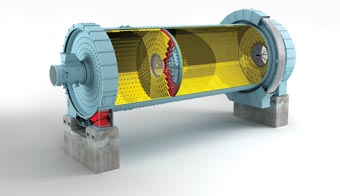

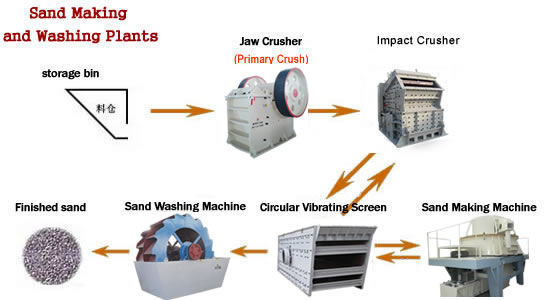

Sand production line (sand making production line) usually consists of vibrating feeder, jaw crusher, sand making machine (direct impact crusher), vibrating screen, sand washing machine, belt conveyor, concentration of electronic equipment composition, design production is commonly 50-500T/H, our company has research and development for several years, will sand making machine and the company has international advanced level of other series of products, design full of sand production line, in a leading position in the industry.

The stone from the vibrating feeder evenly sent to the jaw crusher was broken, broken material into fine coarse jaw crusher again and broken, broken materials by belt conveyor to the sieve screening, meet the sand making machine feeding gravel sand grain of sand, does not meet the requirements of the return fine jaw crusher to crush the material, sand making machine out, return to the vibration sieve re screening, screening the main requirements of full of sand, into the sand washing machine cleaning, cleaning after the finished product conveying belt is finished, sand and gravel mixed material with the main demand, into the sand making machine this production line was broken again, and ultimately the formation of 2 fault circuit, according to the needs of the user can also be a variety of configuration.

Characteristics of sand production line

The research production for many years engaged in sand and gravel crushing my company, based on the sand production line production design field in China and the ordinary sand production line has the following characteristics:

- 1, the investment is only the same processing ability of conventional production line 1/3 - 1/5.

- 2, sand production cost per ton is only regular production line 1/3 - 1/4.

- 3, the production of a high degree of automation, production staff of 3 people in each class of the following.

- 4, investment recovery period is short, generally 3 months to recover the investment.

- 5, a high degree of automation, low operation cost, high crushing ratio, energy saving, high yield, less pollution, easy to repair, the mechanism of sand production in line with national standards for construction sand, uniform particle size, grain shape, reasonable distribution.

Hot Products

Request for Quotation

You can get the price list and a MCC representative will contact you within one business day.